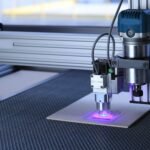

Introduction to CNC Machines

CNC machines, or Computer Numerical Control machines, represent a significant advancement in the field of manufacturing. These sophisticated devices utilize computer programs to control various tools and machinery, enabling automation, consistency, and precision in various manufacturing processes. The core function of a CNC machine is to convert a computer-aided design (CAD) into a precise physical object by directing movement and operation of tools such as lathes, mills, routers, and laser cutters.

The operation of a CNC machine is predicated on the principles of numerical control, wherein a computer interprets a set of instructions and feeds it to the machine. This process not only ensures an elevated level of accuracy but also enhances efficiency by significantly reducing the likelihood of human error. CNC tools, driven by powerful software, allow for complex tasks to be executed with remarkable precision that is difficult to achieve using traditional manufacturing methods.

The history of CNC technology dates back to the mid-20th century, with its origins rooted in the development of the first numerical control machines in the 1940s and 1950s. Initially, these machines were cumbersome and expensive, reliant on punch cards for commands. Over the decades, technological advancements have led to the evolution of CNC into a more versatile, user-friendly, and cost-effective solution for manufacturers. Innovations such as computer programming, real-time monitoring, and improved materials have propelled CNC machines to the forefront of modern manufacturing.

As we delve deeper into the myriad benefits of CNC machines, it is essential to recognize how their evolution has transformed the landscape of manufacturing, setting new standards for efficiency, precision, and innovation across various industries.

Precision and Accuracy

CNC machines, or Computer Numerical Control machines, have revolutionized the manufacturing landscape by providing unmatched precision and accuracy in the production of components. Traditional machining methods often rely heavily on manual skills, which can introduce variability and human error into the manufacturing process. In contrast, CNC technology employs automated tools that follow precise programmed instructions, significantly minimizing room for error and enhancing overall reliability.

One of the primary advantages of CNC machines is their ability to repeat the same task with a high degree of accuracy over extended periods. This repeatability is especially crucial in industries such as aerospace, automotive, and electronics, where the quality of components is paramount. For example, a CNC milling machine can produce multiple identical parts with tolerances as tight as 0.001 inches. This level of precision ensures that each component fits perfectly within the final assembly, thus reducing the risk of malfunctions and increasing the longevity of the product.

Furthermore, the consistency provided by CNC tools in large-scale production runs leads to significant operational efficiencies. Manufacturers can achieve uniform quality across thousands of units without compromising on design complexity. This is particularly beneficial in sectors where product specifications must adhere to strict regulatory standards. In such cases, CNC machines ensure that every piece not only meets the specified dimensions but also adheres to relevant safety and operational guidelines.

In summary, the integration of CNC technology into manufacturing processes enhances precision and accuracy, ultimately shaping the quality of the final products and streamlining production workflows. The ability to produce consistent and reliable components positions industries to meet consumer demands while maintaining high standards of excellence in manufacturing.

Increased Efficiency and Productivity

The introduction of CNC machines has revolutionized modern manufacturing, significantly enhancing efficiency and productivity across various industries. Traditional machining processes often rely heavily on manual labor, which can lead to prolonged production times and inconsistent quality. In contrast, CNC (Computer Numerical Control) machines automate many of these processes, resulting in faster production cycles. With the capability to operate continuously, CNC tools can run unattended, greatly increasing throughput and reducing idle time.

One of the primary advantages of CNC technology is its ability to produce complex designs with precision that would be nearly impossible to achieve using traditional methods. CNC machines can execute intricate patterns and shapes with high accuracy, eliminating the need for multiple setups and manual interventions. This not only streamlines the overall manufacturing process but also allows for greater design flexibility. As a result, manufacturers can quickly pivot to meet changing customer demands, ultimately enhancing their competitiveness in the market.

Case studies across various industries illustrate these improvements. For instance, a notable example comes from an automotive parts manufacturer that implemented CNC machining to replace outdated manual techniques. By transitioning to CNC machines, the company reported a 30% reduction in production time while doubling its output volume. Another example is seen in the aerospace sector, where a manufacturer noted a 50% decrease in setup times and improved resource utilization after adopting CNC tools. These examples highlight how CNC technology not only accelerates the manufacturing process but also allows companies to allocate resources more effectively, further amplifying their productivity.

In conclusion, CNC machines are integral to increasing efficiency in modern manufacturing. Their automation capabilities, precision, and versatility empower businesses to achieve higher levels of productivity and better utilize resources compared to traditional machining methods.

Versatility and Flexibility in Design

CNC machines have revolutionized modern manufacturing by offering unparalleled versatility and flexibility in design. These advanced machines can process a wide array of materials ranging from metals to plastics and composites, enabling manufacturers to adapt to various production needs with ease. The adaptability of CNC tools allows for quick switching between different projects, making it possible to respond proactively to customer specifications and market demands.

One of the standout features of CNC technology is its capability to produce intricate designs with a high degree of precision. Manufacturers can employ CNC machines to create customized solutions tailored to the specific requirements of their clients. This bespoke manufacturing is particularly valuable in industries such as aerospace, automotive, and healthcare, where precision and quality are paramount. For instance, in aerospace, CNC machining is used to manufacture complex components that must meet strict regulatory standards, while in healthcare, the production of customized prosthetics and medical devices relies on the precision enabled by CNC tools.

The ability to seamlessly switch designs is facilitated by CAD (Computer-Aided Design) software, which integrates with CNC machines for streamlined production processes. This integration allows engineers to easily modify designs, ensuring that manufacturers are equipped to handle changes promptly without sacrificing production speed. Consequently, businesses can innovate and bring new products to market at a much faster rate compared to traditional manufacturing methods.

In addition to their adaptability, CNC machines also maintain consistent quality across different production runs. The automation and computer control inherent in CNC technology reduce human error, ensuring that each output meets quality standards, thus enhancing customer satisfaction.

Through these benefits, CNC machines represent a significant leap forward in manufacturing versatility, enabling industries to thrive in a competitive landscape. By leveraging CNC technology, manufacturers can create unique and efficient designs that cater to the specific needs of their customers.